Full-physical Experiment Test

In the research of power and power electronic systems, the traditional way is to integrate the controller into a physical test platform for verification and testing after the controller is designed. The advantage of this method is that the physical process of various phenomena can be directly observed, and it is convenient to accurate test data. The disadvantage is that the construction of the platform requires a relatively high investment in site, capital, time and personnel.

Digital Simulation Test

With the rapid development of computer technology, computer-based digital simulation technology has been widely applied due to its flexibility and diversity advantages. Digital simulation mainly uses mathematical modeling and calculation to simulate the operating characteristics of the objects in the system, and its core is mathematical modeling and calculation. According to the speed of simulation calculation and operation, digital simulation technology is divided into offline simulation (non-real-time) and real-time simulation.

Offline Simulation

Offline simulation is that the response speed of digital simulation model is slower than that of the actual system, that is, observing the operation state of the model for about 1s, and the simulation calculation time is often far more than 1s. Offline simulation software generally runs on ordinary computers, and the time required for its simulation operation is much longer than that of the actual system. The reason is that on the one hand, the operating system and hardware capabilities of the ordinary computer itself are insufficient, and on the other hand, On the other hand, there is no optimization based on real-time operation during modeling and calculation, which leads to poor time certainty. In the field of power and power electronic systems, our commonly used offline simulation software includes PSCAD/EMTDC, MATLAB/Simulink, etc.

Real-Time Simulation

Real-time simulation is that the response speed of the digital simulation model is the same as that of the actual system, that is, 1s of the model simulation running corresponds to 1s of the actual time. Due to the large amount of calculation of power and power electronic system models, it is often necessary to use powerful multi-core CPU or FPGA hardware to perform calculations, and then perform some equivalents and optimizations on real-time simulation modeling and calculations to realize real-time simulation systems. Therefore, in the real-time simulation system, the simulator is an important part, and the simulation scale and computing power of the real-time simulation system are determined by the hardware resources of the simulator.

In digital simulation, because the system can generally be disassembled into the control side and the controlled object side, and the focus of different research topics is different, the part of the system that uses real-time technology will be different, which has derived the concepts of HIL simulation, hardware-in-the-loop (HIL), Rapid Control Prototyping (RCP) and so on.

Hardware-In-the-Loop/HIL Simulation

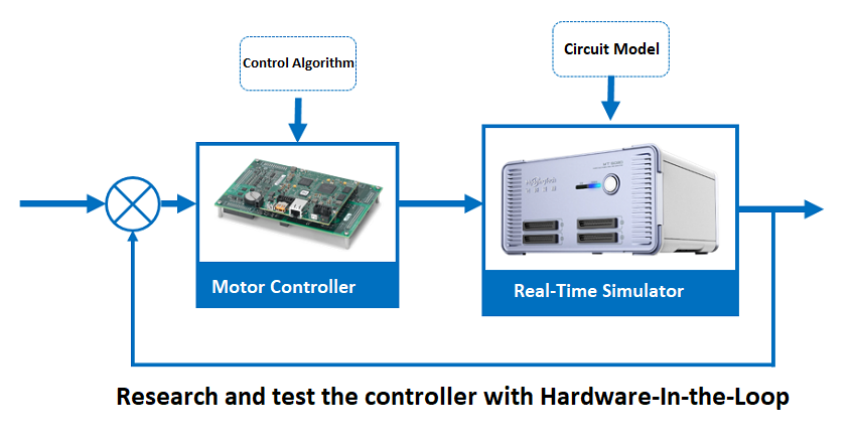

Hardware in the loop simulation, also known as HIL, is an application of a closed-loop test system composed of a real-time simulator and a controller, as shown in the following figure:

The real-time simulator simulates their operating characteristics by running the mathematical models of physical objects in real time. At the same time, the real-time simulator is equipped with an IO board, which interacts with the controller through IO channels. The "hardware" in hardware-in-the-loop simulation means that the control part is no longer a control block diagram in pure software simulation, but a real controller.

In many Chinese literatures, hardware-in-the-loop simulation is often referred to as "HIL simulation", where "physical object" refers to the real controller in the system, because the real-time simulator in this system is not an actual physical device, therefore, we usually call this system "HIL".

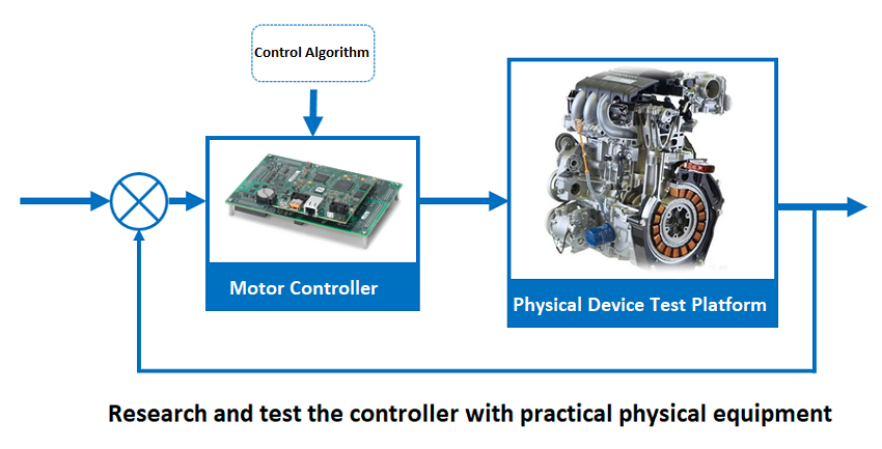

Rapid Control Prototyping/RCP

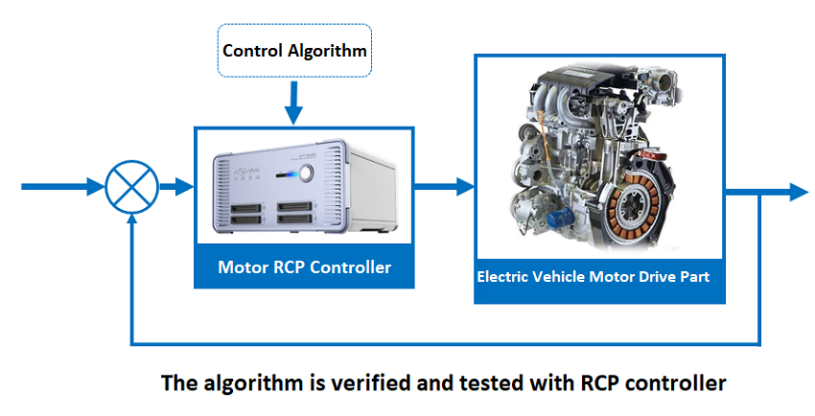

Rapid Control Prototyping, also known as RCP, which refers to the process of debugging and calibrating the control algorithm on the prototype hardware with powerful computing function and IO interface, as shown in the following figure:

The rapid control prototyping platform provides a fast and convenient method to import control algorithms. Its main value is that it can directly run control algorithms built in some advanced graphical environments (such as Simulink), provide ready-made verified control hardware, and shorten the development cycle.